Welcome to Jingmao Tong (Shandong) Metal Products Co., Ltd.

Email :business@sdhmsteel.com Whatsapp :+8613176025308

PRODUCT CENTER

Aluminum Round Pipe

Extruded aluminum pipe is stocked in both seamless and structural (port-hole die).

Aluminium pipe is used in pressure or structural application.

These Aluminium Pipe are light weight, excellent corrosion resistance, and the ability to transmit heat rapidly are only a few of the benefits of aluminum pipes.

Product Details

Product introduction

Aluminium Pipe can be produced in two types drawn and extruded aluminum pipe. Extruded aluminum pipe is stocked in both seamless and structural (port-hole die). Aluminium pipe is used in pressure or structural application. These Aluminium Pipe are light weight, excellent corrosion resistance, and the ability to transmit heat rapidly are only a few of the benefits of aluminum pipes.

There are 2 types of Aluminium Pipe:

1) Aluminium Extruded Pipe: Aluminium Extruded Pipe, formed by hot extruding through a die, is available as a seamless or structural grade product.

2) Aluminium Drawn Pipe: Aluminium Drawn Pipe is a seamless extruded Pipe is brought to final size by drawing through a die.

Technical data

| Aluminium Alloy | ASTM B210, ASTM B234, ASTM B241, ASTM B483; GB/T 6893-2000, GB/T 4437-2000: JIS H4080-2006 |

| Aluminium Pipe American Specifications: | ASTM B210 drawn, ASTM B241 extruded, AMS 4173, AMS 4080, AMS 4082, AMS4083, WW-T-700/6 |

| Aluminium Pipe British Specifications | H20, HE 20 |

| Material | 1060, 1200, 1100, 2024, 2124, 3003, 3004, 5050, 5083, 5154, 5454, 5652, 5086, 5056, 5754, 6061, 6062, 6063, 7075, etc. |

| Aluminium Pipe Standard | ASTM, ASME, AMS, ASTM B210M, GB/T 3191, JIS H4040, ASTM B210, AMS QQ-A-200/9 |

| Aluminium Pipe Temper | O, H12, H14, H16, H18, H22, H24, H26, H32, H112 |

| Aluminium Pipe Form | Aluminium extruded, seamless, drawn and coiled Pipe in Black & Bright Finish |

| Aluminium Pipe Sizes | 1/8″ – 16″ (3mm – 2500mm) OD .020″ – 2″ (.2mm – 150mm) wall (1m-12m) Length |

| Machinability | Fair |

| Weldability | Good |

| Corrosion Resistance | Good |

| Aluminium Pipe | Bright, Polish & Black |

| Aluminium Pipe Surface | Anodized, Oxidation, electrophoresis coating, fluorine carbon spraying, powder coating, wood grain transfer printing, mechanical drawing, mechanical polishing, sand blasting, Polished, hair line, brush, Mill finished, Bright finish, paper interleaved |

| Surface treatment | Nature, Black painting, Transparent oil, rust-proof black oil or hot-dip galvanized |

| Aluminium Pipe Delivery Time | 10-30 days after receiving the prepayment |

| Aluminium Pipe Packaging Details | Export standard package: bundled wooden box, suit for all kinds of transport or be required. |

| ASTM B210 Alloy Pipe Outer packing | Export standard, wooden pallet |

| Here are 6 different types of finishes for extruded aluminum Pipe: |

|

| Applications | Bicycle Parts, aircraft ducting, wheelchair frames, telescopes, machined bushes, air cylinders |

| Aluminum Pipe Features: | |

|---|---|

| 1.Materials | 7001-T6/T9, 7075-T9 alloy |

| 2.High strengh | 660Mpa |

| 3.Light weight | Aluminum alloy is lighter weight |

| 4.Tightness tolerance | a) Inner diameter:±0.02mm b) Outer diameter:±0.02mm |

| 5.Weight | ±0.5% |

| 6.Straightened to 0.12mm | |

Standard Dimensions of Aluminium Pipe

Standard dimensions

|

|

Aluminium Round Pipe Weight Chart

| Product | Diameter | Thickness | Weight | ||

|---|---|---|---|---|---|

| Aluminium Round Pipe | 10 mm | x | 0,7 mm | 0,055 Kg/m | |

| Aluminium Round Pipe | 6 mm | x | 0,8 mm | 0,035 Kg/m | |

| Aluminium Round Pipe | 8 mm | x | 0,8 mm | 0,049 Kg/m | |

| Aluminium Round Pipe | 10 mm | x | 0,8 mm | 0,062 Kg/m | |

| Aluminium Round Pipe | 1/2″ | 12,7 mm | x | 0,8 mm | 0,081 Kg/m |

| Aluminium Round Pipe | 19 mm | x | 0,9 mm | 0,138 Kg/m | |

| Aluminium Round Pipe | 6 mm | x | 1 mm | 0,042 Kg/m | |

| Aluminium Round Pipe | 8 mm | x | 1 mm | 0,059 Kg/m | |

| Aluminium Round Pipe | 3/8″ | 9,5 mm | x | 1 mm | 0,072 Kg/m |

| Aluminium Round Pipe | 11 mm | x | 1 mm | 0,085 Kg/m | |

| Aluminium Round Pipe | 12 mm | x | 1 mm | 0,093 Kg/m | |

| Aluminium Round Pipe | 1/2″ | 12,7 mm | x | 1 mm | 0,099 Kg/m |

| Aluminium Round Pipe | 14 mm | x | 1 mm | 0,110 Kg/m | |

| Aluminium Round Pipe | 16 mm | x | 1 mm | 0,127 Kg/m | |

| Aluminium Round Pipe | 19 mm | x | 1 mm | 0,153 Kg/m | |

| Aluminium Round Pipe | 22 mm | x | 1 mm | 0,178 Kg/m | |

| Aluminium Round Pipe | 25 mm | x | 1 mm | 0,204 Kg/m | |

| Aluminium Round Pipe | 28 mm | x | 1 mm | 0,229 Kg/m | |

| Aluminium Round Pipe | 32 mm | x | 1 mm | 0,263 Kg/m | |

| Aluminium Round Pipe | 10 mm | x | 1,1 mm | 0,083 Kg/m | |

| Aluminium Round Pipe | 19 mm | x | 1,1 mm | 0,167 Kg/m | |

| Aluminium Round Pipe | 17 mm | x | 1,2 mm | 0,161 Kg/m | |

| Aluminium Round Pipe | 19 mm | x | 1,2 mm | 0,181 Kg/m | |

| Aluminium Round Pipe | 22 mm | x | 1,2 mm | 0,212 Kg/m | |

| Aluminium Round Pipe | 3/8″ | 9,5 mm | x | 1,3 mm | 0,090 Kg/m |

| Aluminium Round Pipe | 11 mm | x | 1,3 mm | 0,107 Kg/m | |

| Aluminium Round Pipe | 16 mm | x | 1,5 mm | 0,184 Kg/m | |

| Aluminium Round Pipe | 19 mm | x | 1,5 mm | 0,223 Kg/m | |

| Aluminium Round Pipe | 25 mm | x | 1,5 mm | 0,299 Kg/m | |

| Aluminium Round Pipe | 28 mm | x | 1,5 mm | 0,337 Kg/m | |

| Aluminium Round Pipe | 32 mm | x | 1,5 mm | 0,388 Kg/m | |

| Aluminium Round Pipe | 35 mm | x | 1,5 mm | 0,426 Kg/m | |

| Aluminium Round Pipe | 38 mm | x | 1,5 mm | 0,464 Kg/m | |

| Aluminium Round Pipe | 45 mm | x | 1,5 mm | 0,553 Kg/m | |

| Aluminium Round Pipe | 50 mm | x | 1,5 mm | 0,617 Kg/m | |

| Aluminium Round Pipe | 60 mm | x | 1,5 mm | 0,744 Kg/m | |

| Aluminium Round Pipe | 40 mm | x | 1,7 mm | 0,552 Kg/m | |

| Aluminium Round Pipe | 20 mm | x | 2 mm | 0,305 Kg/m | |

| Aluminium Round Pipe | 25 mm | x | 2 mm | 0,390 Kg/m | |

| Aluminium Round Pipe | 30 mm | x | 2 mm | 0,475 Kg/m | |

| Aluminium Round Pipe | 40 mm | x | 2 mm | 0,645 Kg/m | |

| Aluminium Round Pipe | 50 mm | x | 2 mm | 0,814 Kg/m | |

| Aluminium Round Pipe | 50 mm | x | 2 mm | 0,814 Kg/m | |

| Aluminium Round Pipe | 70 mm | x | 2 mm | 1,154 Kg/m | |

| Aluminium Round Pipe | 90 mm | x | 2 mm | 1,493 Kg/m | |

| Aluminium Round Pipe | 114 mm | x | 2 mm | 1,900 Kg/m | |

| Aluminium Round Pipe | 4″1⁄2 | 114,3 mm | x | 2 mm | 1,905 Kg/m |

| Aluminium Round Pipe | 30 mm | x | 2,5 mm | 0,583 Kg/m | |

| Aluminium Round Pipe | 60 mm | x | 2,5 mm | 1,219 Kg/m | |

| Aluminium Round Pipe | 45 mm | x | 3 mm | 1,069 Kg/m | |

| Aluminium Round Pipe | 60 mm | x | 3 mm | 1,450 Kg/m | |

| Aluminium Round Pipe | 70 mm | x | 3 mm | 1,705 Kg/m | |

| Aluminium Round Pipe | 35 mm | x | 4 mm | 1,052 Kg/m | |

| Aluminium Round Pipe | 90 mm | x | 5 mm | 3,605 Kg/m | |

Aluminium Square Pipe Weight Chart

| Product | Side | Thickness | Weight | |

|---|---|---|---|---|

| Aluminium Square Pipe | 16 mm | x | 0,7 mm | 0,116 Kg/m |

| Aluminium Square Pipe | 16 mm | x | 0,9 mm | 0,147 Kg/m |

| Aluminium Square Pipe | 19 mm | x | 0,9 mm | 0,176 Kg/m |

| Aluminium Square Pipe | 12,5 mm | x | 1 mm | 0,124 Kg/m |

| Aluminium Square Pipe | 16 mm | x | 1 mm | 0,162 Kg/m |

| Aluminium Square Pipe | 19 mm | x | 1 mm | 0,194 Kg/m |

| Aluminium Square Pipe | 20 mm | x | 1 mm | 0,205 Kg/m |

| Aluminium Square Pipe | 25 mm | x | 1 mm | 0,259 Kg/m |

| Aluminium Square Pipe | 12 mm | x | 1,5 mm | 0,170 Kg/m |

| Aluminium Square Pipe | 20 mm | x | 1,5 mm | 0,300 Kg/m |

| Aluminium Square Pipe | 30 mm | x | 1,5 mm | 0,462 Kg/m |

| Aluminium Square Pipe | 40 mm | x | 1,5 mm | 0,624 Kg/m |

| Aluminium Square Pipe | 50 mm | x | 1,5 mm | 0,786 Kg/m |

| Aluminium Square Pipe | 20 mm | x | 2 mm | 0,389 Kg/m |

| Aluminium Square Pipe | 40 mm | x | 2 mm | 0,821 Kg/m |

| Aluminium Square Pipe | 60 mm | x | 2 mm | 1,253 Kg/m |

| Aluminium Square Pipe | 65 mm | x | 2 mm | 1,361 Kg/m |

| Aluminium Square Pipe | 100 mm | x | 2 mm | 2,117 Kg/m |

Aluminium Rectangular Pipe Weight Chart

| Product | A | B | Thickness | Weight | ||

|---|---|---|---|---|---|---|

| Aluminium Rectangular Pipe | 30 mm | x | 15 mm | x | 1,5 mm | 0,340 Kg/m |

| Aluminium Rectangular Pipe | 40 mm | x | 20 mm | x | 1,5 mm | 0,462 Kg/m |

| Aluminium Rectangular Pipe | 50 mm | x | 25 mm | x | 1,5 mm | 0,583 Kg/m |

| Aluminium Rectangular Pipe | 60 mm | x | 40 mm | x | 2 mm | 1,037 Kg/m |

| Aluminium Rectangular Pipe | 65 mm | x | 30 mm | x | 1,5 mm | 0,745 Kg/m |

| Aluminium Rectangular Pipe | 80 mm | x | 30 mm | x | 1,5 mm | 0,867 Kg/m |

| Aluminium Rectangular Pipe | 80 mm | x | 20 mm | x | 2 mm | 1,037 Kg/m |

| Aluminium Rectangular Pipe | 85 mm | x | 30 mm | x | 1,8 mm | 1,083 Kg/m |

| Aluminium Rectangular Pipe | 100 mm | x | 50 mm | x | 4 mm | 3,067 Kg/m |

Standard Specification of Aluminium Pipe

Standards and specifications by country

| Specification | Alloy | Temper | Company |

|---|---|---|---|

| Europe | |||

| EN 2089/2395 | 2014A | T6(T62)/T4(T42) | |

| EN 2087/2088 | 2014A clad | T6(T62)/T4(T42) | |

| EN 4101 | 2024 | T4 | |

| EN 2090/2091/2703/4001 | 2024 clad cmq | T3/T4/T4(T42)/T351 | |

| EN 3474/3997/3998/3999 | 2024 cmq | T81/T3/T4(T42)/T351 | |

| EN 2694/EN 3341 | 6061 | T6(T62)/T4(T42) | |

| EN 4449/4450 | 7050 | T76/F(T762) | |

| EN 2696 | 7075 | T6(T62) | |

| EN 2092 | 7075 clad | T6(T62) | |

| EN 2802/3333 | 7475 | T761/F(T762) | |

| EN 2803/3332 | 7475 clad | T761/F(T762) | |

| France | |||

| AIR 9048.010/.030/ | 2014 | F(T42)/F(T62)/T4/ | |

| .020/.040/.050 | 2014 | T6/T451 | |

| AIR 9048.060/.080/.070/.090 | 2014 clad | F(T42)/F(T62)/T4/T6 | |

| AIR 9048.100/.110/.120 | 2024 | ||

| AIR 9048.130/.140 | 2024 clad | F(T42)/T3 | |

| AIR 9048.150 | 2618A | H28(T62) | |

| AIR 9048.170 | 2618A clad | H28(T62) | |

| AIR 9048.190/.200 | 5086 | O, H111/H22, H32 | |

| AIR 9048.210/.220/.230/.240 | 6061 | O, H111(T42)/T4/ O, H111(T62)/T6 | |

| AIR 9048.260/.270 | 7075 | T6/T76 | |

| AIR 9048.280 | 7075 clad | T6 | |

| AIR 9048.290 | 7475 | T76 | Boeing |

| Germany | |||

| W.-Nr. 3.1254 | 2014A | T4, T6 | |

| W.-Nr. 3.1354 | 2024 | O(T42), T3 | |

| W.-Nr. 3.1364 | 2024 clad | O(T42), T3 | |

| W.-Nr. 3.3214 | 6061 | O(T62), T6 | |

| W.-Nr. 3.4364 | 7075 | T6 | |

| W.-Nr. 3.4374 | 7075 clad | O(T62), T6 | |

| W.-Nr. 3.4377 | 7475 clad | T76 | |

| UK | |||

| BS L16/17 | 1200 | H4/O | |

| BS L156/157/158*/159* | 2014A | ||

| 158*/159* | 2014A clad | (T42)(T62) | BAE Systems |

| BS L163/164/165 | 2014A clad | T3/F(T42), T4/T6 | |

| BS L166*/167* | 2014A clad | F(T42), T4/T6 | |

| BS L109/110 | 2024 clad | T3/F(T42) | |

| DTD5070 | 2618A clad | T6 | |

| BS L59/60/61 | 3103 | H6/H2/O | |

| BS L80/81 | 5251 | O/H6 | |

| BS L113 | 6082 | T4, T6 | |

| BS L88 | 7075 clad | T6 | |

| USA | |||

| AMS QQ-A-250/3 | 2014 clad | O, T4, T6 | |

| AMS QQ-A-250/4 | 2024 | O, T3 | |

| AMS 4037 | 2024 | T3 | |

| AMS QQ-A-250/5 | 2024 clad | O, T3 | |

| AMS 4041 | 2024 clad | T3 | |

| AMS QQ-A-250/30 | 2219 | O(T62), T31(T81), T37(T87) | |

| AMS QQ-A-250/2 | 3003 | O, H14 | |

| AMS 4347 | 6013 | T4 | |

| AMS 4216 | 6013 | T6 | |

| AMS 4025/4026/4027 | 6061 | O, F, T4, T42, T45, T6, T62, T651 | |

| AMS QQ-A-250/12 | 7075 | O, T6, T73 | |

| AMS QQ-A-250/24 | 7075 | T76 | |

| AMS QQ-A-250/13 | 7075 clad | O, T6, T73 | |

| AMS QQ-A-250/26 | 7075 clad with 7011 | T76 | |

| AMS QQ-A-250/25 | 7075 clad with 7072 | T76 | |

| European Standard | BS (OLD) | USA (AA) | GERMANY (DIN) | ISO | IS | Canadian |

|---|---|---|---|---|---|---|

| EN AW-1050 A | 1E | 1050 | Al99.5 | Al99.5 | 19500, 19501 | 1 S |

| EN AW-1070 A | – | 1070 | Al-99.7 | Al-99.7 | 19700 | – |

| EN AW-1100 | IC | 1100 | Al-99.0 | Al-99.0 | 19000 | 2 S |

| EN AW-2011 | FC1 | 2011 | AlCuBiPb | AlCu6BiPb | – | 28S |

| EN AW-2014 | HE15 | 2014 | AlCuSiMn | AlCu4SiMg | 24345 | B26S |

| EN AW-2024 | – | 2024 | AlCuMg2 | AlCu4Mg1 | – | 24 S |

| EN AW-3003 | N3 | 3003 | AlMnCu | AlMn1Cu | 31000 | 3 S |

| EN AW-3103 | – | 3103 | – | AlMn1 | – | – |

| EN AW-6101A | E91E | 6101 | E AlMgSi 0.5 | E AlMgSi(A) | 63401 | D50S |

| EN AW-6005 | – | 6005 | AlMgSi0.7 | AlSiMg | 62400 | C51S |

| EN AW-6351 | HE30 | 6351 | AlMgSi1 | AlSiMg0.5Mn | 64430 | B51S |

| EN AW-6060 | – | 6060 | AlMgSi 0.5 | AlMgSi | – | – |

| EN AW-6061 | HE20 | 6061 | AlMgSiCu | AlMg1SiCu | 65032 | 65S |

| EN AW-6063 | HE9 | 6063 | AlMgSi0.5 | AlMg0.7Si | 63400 | 50S |

| EN AW-6082 | HE30 | 6351 | AlMgSi1 | AlSi1MgMn | 64430 | B51S |

Aluminium Pipe Equivalent Grades

| China | U.S.A. | BRITAIN | CANADA | GERMANY | RUSSIA | I.S.O. | FRENCH | |

|---|---|---|---|---|---|---|---|---|

| New IS | Old IS | (A.A.) | (B.S.) | (DIN) | – | – | – | |

| 19501 | 1E | 1050(E.C.) | 1E | C 1S | E-Al 99.5 | – | Al-99.5 | 1050A |

| 19500 | 1B | 1050 | 1B | 1S | A-99.5 | – | – | – |

| 19600 | – | 1060 | – | – | – | – | Al-99.7 | – |

| 19700 | – | 1070 | – | – | Al-99.7 | – | Al-99.8 | – |

| 19800 | 1A | 1080 | 1A | – | – | – | Al-99.0 | 1200 |

| 19000 | 1C | 1100 | 1C | 2S | Al-99.0 | AD | Al-Cu-6 Bi Pb | 2011 |

| – | – | 2011 | FC1 | 28S | Al-Cu-Bi-Pb | – | – | – |

| 24345 | H15 | 2014 | H15 | B26S | Al-Cu-Si | AK | Al-Cu-4Mg Si | – |

| 24534 | H14 | 2017 | H14 | 17S/16S | – | D1 | Al-Cu-4Mg 1 | 2024 |

| – | – | 2024 | – | 24S | Al-Cu-Mg.2 | – | AlCu-4PbMg | 2030 |

| – | – | 2030 | – | – | Al-Cu-Mg-Pb | – | Al-Cu2-Mg1.5-Ni | 2618 |

| – | – | 2618 | 2618 | – | – | – | A-Mn 1 | 3003 |

| 31000 | N3 | 3003 | N3 | 3S | Al-Mn | A-Mn | Al Mn 1 Mg 1 | 3004 |

| – | – | 3004 | – | Al-Mn.1-Mg.1 | Al Mn 1 Mg 0.50 | 3005 | ||

| – | – | 3005 | – | Al-Mn.1-Mg.0.50 | Al-Si5 | 4043 | ||

| 43000 | N21 | 4043 | N21 | 33S | Al-Si-5 | AK | – | – |

| 46000 | N2 | 4047 | N2 | 35S | – | – | A-Mg-1 | – |

| 51000 | – | 5005 | – | B57S | – | – | Al-Mg-2 | 5251 |

| 5051 | 5251 | Al-Mg.2 Mn.0.30 | A-Mg-2.5 | 5051 | ||||

| 52000 | N4 | 5052 | N4 | M57S | Al-Mg.2 | A-Mg | A-Mg-4 | – |

| 53000 | N5 | 5086 | N5 | 54S | – | A-Mg-3 | Al-Mg-4.5 Mn | 5083 |

| 54300 | N8 | 5083 | N8 | D54S | Al-Mg-4.5 Mn | – | Al-Mg.5 | 5356 |

| 55000 | N6 | 5056 | N6 | A56S | Al-Mg.5 | – | Al-Mg.3-Mn | 5454 |

| 5454 | 5454 | Al-Mg.2.7-Mn | – | Al.Mg.3 | 5754 | |||

| 5754 | Al-Mg.3 | Al-Mg-1Si Cu | – | |||||

| 65032 | H20 | 6061 | H20 | 65S | Al-Mg-Si Cu | – | Al-Mg-Si | – |

| 63400 | H9 | 6063 | H9 | 50S | Al-Mg-Si 0.5 | – | Al-Si-1 Mg | 6081 |

| 64430 | H30 | 6351 | H30 | B51S | Al-Mg-Si 1 | AV | Al-Si-1 Mg Mn | 6082 |

| 6082 | 6082 | Al-Mg-Si 1 | – | – | – | |||

| 64423 | H11 | 6066 | H11 | C62S | – | – | – | |

| 62400 | – | 6005 | – | C51S | – | – | – | – |

| 63401 | 91E | 6101 | 91E | D50S | E.Al.Mg.Si 0.5 | – | – | – |

| 64401 | – | 6201 | – | – | – | – | – | |

| – | – | 7020 | 7020 | – | – | – | 7020 | |

| 74530 | – | 7039 | – | D74S | – | – | 3004 | |

| – | – | 7075 | DTD-5124 | 75S | – | Al-Zn 6 Mg Cu | 7075 | |

| 40800 | 8011 | – | Al-Fe-Si | 8011 | ||||

Aluminium Pipe Chemical Composition

| ALUMINIUM Alloy | % Si |

% Mg |

% Mn |

% Cu |

% Fe |

% Cr |

% Zn |

% Ti |

% Others |

% Al |

|---|---|---|---|---|---|---|---|---|---|---|

| EN AW-1050 A | 0.25 Max |

0.05 Max |

0.05 Max |

0.05 Max |

0.40 Max |

– | 0.07 Max |

0.05 Max |

– | 99.5 Min |

| EN AW-1070 A | 0.20 Max |

0.03 Max |

0.03 Max |

0.03 Max |

0.25 Max |

– | 0.07 Max |

0.03 Max |

– | 99.7 Min |

| EN AW-1100 | Si+Fe 0.95 Max | – | 0.05 Max | 0.05 – 0.20 | – | – | 0.10 Max | 0.05 Max | – | 99.0 Min |

| EN AW-2011 | 0.40 Max | – | – | 5.00 – 6.00 | 0.70 Max | – | 0.30 Max | – | Bi : 0.20 – 0.60 Pb : 0.20 – 0.60 |

Remainder |

| EN AW-2014 | 0.50 – 1.20 | 0.20 – 0.80 | 0.40 – 1.20 | 3.90 – 5.00 | 0.70 Max | 0.10 Max | 0.25 Max | 0.15 Max | – | Remainder |

| EN AW-2024 | 0.50 Max | 1.20 -1.80 | 0.30 – 0.90 | 3.80 – 4.90 | 0.50 Max | 0.10 Max | 0.25 Max | 0.15 Max | 0.15 Max | Remainder |

| EN AW-3003 | 0.60 Max | – | 1.00 – 1.50 | 0.05 – 0.20 | 0.70 Max | – | 0.10 Max | – | 0.15 Max | Remainder |

| EN AW-3103 | 0.50 Max | 0.30 Max | 0.90 – 1.50 | 0.10 Max | 0.70 Max | 0.10 Max | 0.20 Max | 0.10 Max | – | Remainder |

| EN AW-6101A | 0.30 – 0.7 | 0.40 – 0.90 | 0.03 Max | 0.05 Max | 0.40 Max | – | – | – | 0.10 Max | Remainder |

| EN AW-6005 | 0.60 – 0.90 | 0.40 – 0.60 | 0.10 Max | 0.10 Max | 0.35 Max | 0.10 Max | 0.10 Max | 0.10 Max | – | Remainder |

| EN AW-6351 | 0.70 – 1.30 | 0.40 – 0.80 | 0.40 – 0.80 | 0.10 Max | 0.50 Max | – | 0.20 Max | 0.20 Max | 0.15 Max | Remainder |

| EN AW-6060 | 0.30 – 0.60 | 0.35 – 0.60 | 0.10 Max | 0.10 Max | 0.10 – 0.30 | 0.05 Max | 0.15 Max | 0.10 Max | – | Remainder |

| EN AW-6061 | 0.40 – 0.80 | 0.80 – 1.20 | 0.15 Max | 0.15 – 0.40 | 0.70 Max | 0.04 – 0.35 | 0.25 Max | 0.15 Max | – | Remainder |

| EN AW-6063 | 0.20 – 0.60 | 0.45 – 0.90 | 0.10 Max | 0.10 Max | 0.35 Max | 0.10 Max | 0.10 Max | 0.10 Max | – | Remainder |

| EN AW-6082 | 0.70 – 1.30 | 0.60 -1.20 | 0.40 – 1.00 | 0.10 Max | 0.50 Max | 0.25 Max | 0.20 Max | 0.10 Max | – | Remainder |

Aluminium Pipe Mechanical Properties

| Alloy | Temper | UTS (Mpa) | Yield Strength (Mpa) | Elongation (%) | ||

| Minimum | Maximum | Minimum | Maximum | A 50mm (Minimum) | ||

| EN AW-1050 A | F | 60 | – | 20 | – | 23 |

| O | 60 | 95 | 20 | – | 23 | |

| EN AW-1070 A | F | 60 | – | 20 | – | 23 |

| EN AW-1100 | O | 75 | 110 | – | – | 25 |

| EN AW-2011 | T4 | 275 | – | 125 | – | 12 |

| T6 | 310 | – | 230 | – | 6 | |

| EN AW-2014 | O | – | 250 | – | 135 | 10 |

| T4 | 370 | – | 230 | – | 11 | |

| T6 | 415 | – | 370 | – | 5 | |

| EN AW-2024 | O | – | 250 | – | 150 | 10 |

| T3,T3510,T3511 | 395 | – | 290 | – | 6 | |

| T8,T8510,T8511 | 455 | – | 380 | – | 4 | |

| EN AW-3003 | F | 95 | – | 35 | – | 20 |

| O | 95 | 135 | 35 | – | 20 | |

| EN AW-3103 | F | 95 | – | 35 | – | 20 |

| O | 95 | 135 | 35 | – | 20 | |

| EN AW-6101A | T6 | 200 | – | 170 | – | 8 |

| EN AW-6005 | T4 | 180 | – | 90 | – | 13 |

| T6 | 270 | – | 225 | – | 6 | |

| EN AW-6351 | O | – | 160 | – | 110 | 12 |

| T4 | 205 | – | 110 | – | 12 | |

| T6 | 290 | – | 250 | – | 6 | |

| EN AW-6060 | T4 | 120 | – | 60 | 14 | 12 |

| T5 | 160 | – | 120 | – | 6 | |

| T6 | 190 | – | 150 | – | 6 | |

| T64 | 180 | – | 120 | – | 10 | |

| T66 | 215 | – | 160 | – | 6 | |

| EN AW-6061 | O | – | 150 | – | 110 | 14 |

| T4 | 180 | – | 110 | – | 13 | |

| T6 | 260 | – | 240 | – | 6 | |

| EN AW-6063 | O | – | 130 | – | – | 16 |

| T4 | 130 | – | 65 | – | 12 | |

| T5 | 175 | – | 130 | – | 6 | |

| T6 | 215 | – | 170 | – | 6 | |

| T66 | 245 | – | 200 | – | 6 | |

| EN AW-6082 | O | – | 160 | – | 110 | 12 |

| T4 | 205 | – | 110 | – | 12 | |

| T5 | 270 | – | 230 | – | 6 | |

| T6 | 290 | – | 250 | – | 6 | |

Aluminum Alloy Heat Treatment Temper Designations for Pipes

Basic Aluminum Heat Treatment Designations

F As Fabricated

O Annealed

H Strain Hardened

W Solution Heat Treated

T Solution Heat Treated

Heat Treating T Temper Codes for Aluminium Pipe

T1 – Cooled from an elevated temperature shaping process and naturally aged to a substantially stable condition.

T2 – Cooled from an elevated temperature shaping process, cold worked, and naturally aged to a substantially stable condition.

T3 – Solution heat treated, cold worked, and naturally aged to a substantially stable condition.

T4 – Solution heat treated, and naturally aged to a substantially stable condition.

T5 – Cooled from an elevated temperature shaping process then artificially aged.

T6 – Solution heat treated then artificially aged.

T7 – Solution heat treated then overaged/stabilized.

T8 – Solution heat treated, cold worked, then artificially aged.

T9 – Solution heat treated, artificially aged, then cold worked.

T10 – Cooled from an elevated temperature shaping process, cold worked, then artificially aged.

Additional digits may be used after the first T temper digit to indicate subsequent stress relieving by processes such as stretching, compressing, or a combination.

H Temper Strain Hardening Codes for Aluminium Pipe

H1 – Strain hardened only

H2 – Strain hardened and partially annealed

H3 – Strain hardened and stabilized

H4 – Strain hardened and lacquered or painted. This assumes that thermal affects from the coating process affect the strain hardening; seldom encountered.

Factory profile

Adhering to the tenet of "integrity first, quality for survival", the company has established a complete marketing channel of "based in North China, radiating the whole country, and facing the world", and has not only established a solid strategic partnership with many domestic and foreign enterprises.We have been committed to product development, production and sales, after more than ten years of efforts, our products have been widely used in various fields.

Packing method: Packing according to customer's requirement.

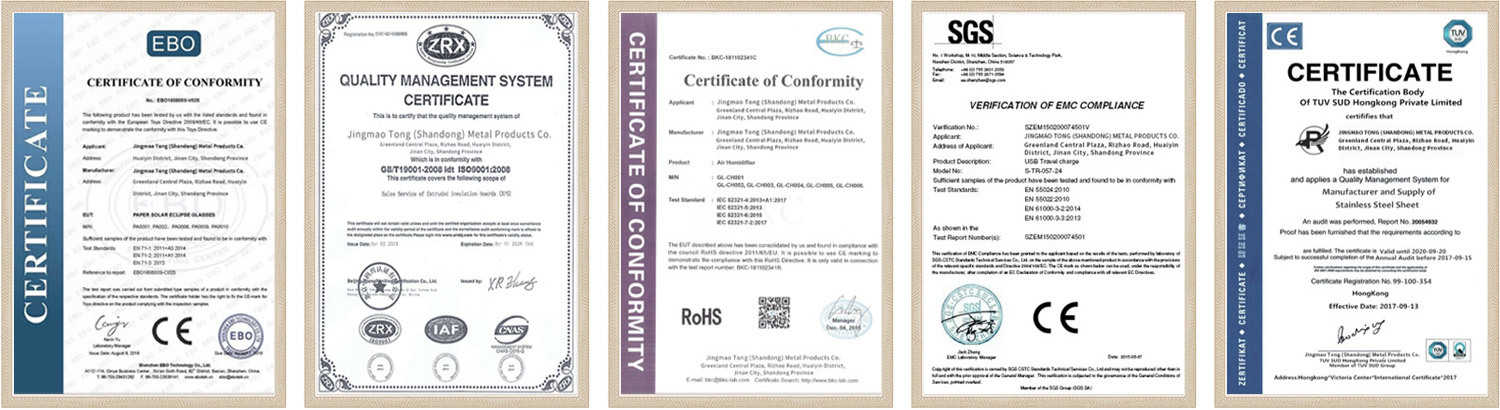

The company has more than 110,000 square meters of production and processing base, fully introduced the international advanced modern automatic production and processing equipment, and took the lead in passing the ISO9001, TS16949, BV, SGS and other international well-known institutions certification.The products are mainly exported to Italy, Mexico, South Korea, Israel, Turkey, India, Pakistan, Kyrgyzstan, Oman, Kazakhstan, Vietnam, Myanmar and other countries. The company's supply is sufficient, the variety is complete, order production is fast, welcome domestic and foreign manufacturers, traders to contact us.

Company Advantages

1. We are a large-scale production enterprise integrating production, research and development, and can customize the products required by customers.

2. We have a perfect after-sales service system, which can track the problems encountered by customers in production at any time and provide corresponding technical support, so as to share our high-quality resources with customers.

3. After more than ten years of development, the company has complete product varieties and large inventory, which can be delivered in the shortest time.

4. Free samples are available.

5. With obvious price advantage, the company has complete production process, from raw materials to finished products integrated production can maximize the cost savings.

QUESTIONS AND ANSWERS

1. Can you make a discount on your price?

2. Do you have any compensation if the goods do not arrive on time?

3. Can I add my own Logo to the purchased products?

4. Can you compensate for the damage in transit?

APPLICATION FIELD

Steel Structure

Steel Structure

Petroleum

Petroleum

Boiler

Boiler

Architecture

Architecture

A Ship

A Ship

Bridge

Bridge

Chemical Plant

Chemical Plant

Oceanographic Engineering

Oceanographic Engineering

RELATED PRODUCTS

GET A FREE QUOTE