Welcome to Jingmao Tong (Shandong) Metal Products Co., Ltd.

Email :business@sdhmsteel.com Whatsapp :+8613176025308

PRODUCT CENTER

5140 Steel Plate 1.7035 41Cr4 SCr440 Alloy Steel

Product Details

Product introduction

What is AISI 5140 steel ?

ASTM grade 5140 is one structural alloy steel grade in ASTM A29 standard for general application. 5140 steel plate is widely used in low and moderately stressed parts for vehicles, engines and machines where hard, wear resisting surface is needed. We are professional 5140 plate & round bar supplier and we keep wide size range for 5140 plate in stock for immediate shipment. Contact us for any AISI 5140 plate material request and best 5140 grade steel price.

Competitive Advantage for AISI 5140 material steel plate:

- Available in stock for immediate shipment

- High strength,

- High tenacity

- Good hardenability

- High resistance to thermal properties.

- Competitive price

1. Supply Range of AISI/ASTM 5140

Round Bar: diameter 20mm – 300mm

Steel Plate and Steel Block: thickness 10-200mm x width 300-2000mm

- 10-80mm thickness 5140 plate are available all the time in stock,

- 90-200mm thickness plate to be newly production in 15-30 days lead time.

Surface Finish: Black Surface, Milled Surface or Polished Surface as per given requirements.

Technical data

2. Relevant AISI 5140 Specification and Equivalent Steel Grades

| Country | USA | German | Japan |

| Standard | ASTM/AISI A29 | EN 10083-3 | JIS G4053 |

| Grades | 5140 | 41Cr4 | SCr440 |

3. ASTM 5140 Material Chemical Composition and Equivalent

| Standard | Grade/Steel Number | C | Mn | P | S | Si | Cr | Ni |

| ASTM A29 | 5140 | 0.38-0.43 | 0.70-0.90 | ≤0.035 | ≤0.040 | 0.15-0.35 | 0.70-0.90 | – |

| EN 10083-3 | 41Cr4 / 1.7035 | 0.38-0.45 | 0.60-0.90 | ≤0.025 | ≤0.035 | ≤0.40 | 0.90-1.20 | – |

| JIS G4053 | SCr440 | 0.38-0.43 | 0.60-0.90 | ≤0.030 | ≤0.030 | 0.15-0.35 | 0.90-1.20 | ≤0.25 |

4. AISI 5140 Steel Properties

| Property | Value in metric unit | Value in US unit | ||

| Density | 7.872 *10³ | kg/m³ | 491.4 | lb/ft³ |

| Modulus of elasticity | 205 | GPa | 29700 | ksi |

| Thermal expansion (20 ºC) | 12.6*10-6 | ºCˉ¹ | 7.00*10-6 | in/(in* ºF) |

| Specific heat capacity | 452 | J/(kg*K) | 0.108 | BTU/(lb*ºF) |

| Thermal conductivity | 44.7 | W/(m*K) | 310 | BTU*in/(hr*ft²*ºF) |

| Electric resistivity | 2.28*10-7 | Ohm*m | 2.28*10-5 | Ohm*cm |

| Tensile strength (annealed) | 572 | MPa | 83000 | psi |

| Yield strength (annealed) | 293 | MPa | 42500 | psi |

| Elongation (annealed) | 29 | % | 29 | % |

| Hardness (annealed) | 85 | RB | 85 | RB |

| Tensile strength (normalized) | 793 | MPa | 115000 | psi |

| Yield strength (normalized) | 472 | MPa | 68500 | psi |

| Elongation (normalized) | 23 | % | 23 | % |

| Hardness (normalized) | 98 | RB | 98 | RB |

5. Forging of 5140 Alloy Steel

Hot forming temperature: 1050-850℃.

6. ASTM 5140 Steel Heat Treat

- Soft Annealing

Heat to 680-720℃, cool slowly. This will produce a maximum 5140 hardness of 241HB (Brinell hardness).

- Noramlizing of steel grade 5140

Temperature: 840-880℃.

- Hardening of 5140 forged steel

Harden from a temperature of 820-850, 830-860℃ followed by water or oil quenching.

- Tempering of SAE 5140 material

Tempering temperature: 540-680℃.

7. Applications of AISI Grade 5140

AISI 5140 steel can be used for low and moderately stressed parts for vehicles, engines and machines where hard, wear resisting surface is needed. Hardness as surface hardened about 54 HRC. SAE 5140 steels can also be for marine engineering industry, chemical processing plants, boiler & pressure vessels, nuclear power plants etc.

If you have queries about the 5140 specs, or any questions about the 5140 vs 4130, 5140 vs 4340 etc, please contact us for technical support any time.

Factory profile

Adhering to the tenet of "integrity first, quality for survival", the company has established a complete marketing channel of "based in North China, radiating the whole country, and facing the world", and has not only established a solid strategic partnership with many domestic and foreign enterprises.We have been committed to product development, production and sales, after more than ten years of efforts, our products have been widely used in various fields.

Packing method: Packing according to customer's requirement.

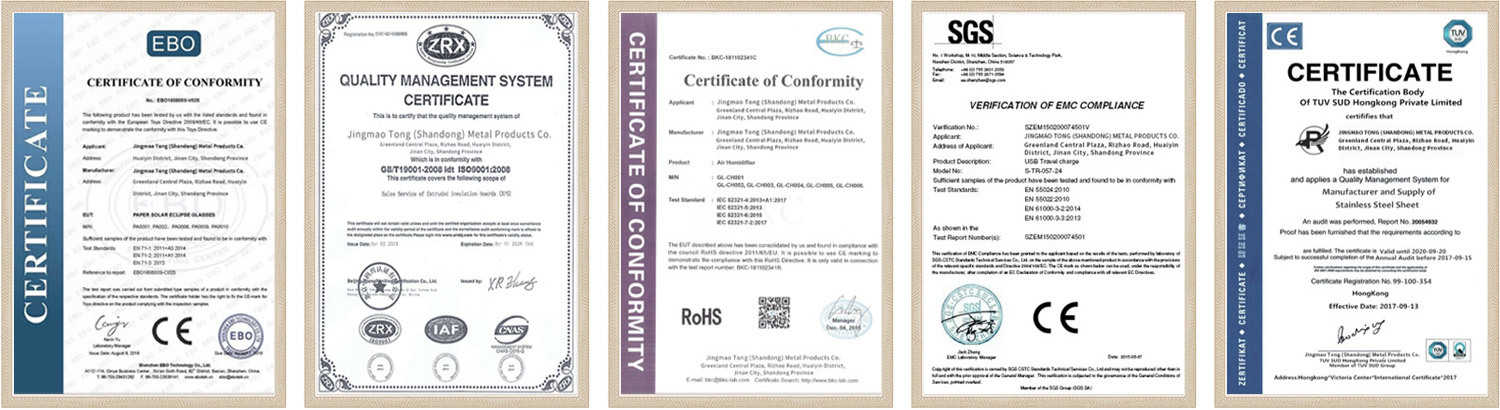

The company has more than 110,000 square meters of production and processing base, fully introduced the international advanced modern automatic production and processing equipment, and took the lead in passing the ISO9001, TS16949, BV, SGS and other international well-known institutions certification.The products are mainly exported to Italy, Mexico, South Korea, Israel, Turkey, India, Pakistan, Kyrgyzstan, Oman, Kazakhstan, Vietnam, Myanmar and other countries. The company's supply is sufficient, the variety is complete, order production is fast, welcome domestic and foreign manufacturers, traders to contact us.

Company Advantages

1. We are a large-scale production enterprise integrating production, research and development, and can customize the products required by customers.

2. We have a perfect after-sales service system, which can track the problems encountered by customers in production at any time and provide corresponding technical support, so as to share our high-quality resources with customers.

3. After more than ten years of development, the company has complete product varieties and large inventory, which can be delivered in the shortest time.

4. Free samples are available.

5. With obvious price advantage, the company has complete production process, from raw materials to finished products integrated production can maximize the cost savings.

QUESTIONS AND ANSWERS

1. Can you make a discount on your price?

2. Do you have any compensation if the goods do not arrive on time?

3. Can I add my own Logo to the purchased products?

4. Can you compensate for the damage in transit?

APPLICATION FIELD

Steel Structure

Steel Structure

Petroleum

Petroleum

Boiler

Boiler

Architecture

Architecture

A Ship

A Ship

Bridge

Bridge

Chemical Plant

Chemical Plant

Oceanographic Engineering

Oceanographic Engineering

RELATED PRODUCTS

GET A FREE QUOTE