Welcome to Jingmao Tong (Shandong) Metal Products Co., Ltd.

Email :business@sdhmsteel.com Whatsapp :+8613176025308

PRODUCT CENTER

ASTM A514 high strength steel plate

Classification :

Product Details

Product introduction

ASTM A514 Alloy Steel Plate

The A514 plate steels are a group of quenched and tempered alloys with many attractive advantages and characteristics. It has a minimum tensile strength of 100 ksi (689 MPa) and at least 110 ksi (758 MPa) ultimate. Plates from 2.5 inches to 6.0 inches have a specified tensile strength of 90 ksi (621 MPa) and 100 - 130 ksi (689 - 896 MPa) ultimate. A514 plate also provides good weldability, and toughness at low atmospheric temperatures. The ASTM A514 group is designed for a wide range of structural uses as well as machinery and equipment. However, the primary use is as a structural steel in building construction. This group of steel, which also includes A517, alloy steel combine optimum strength, toughness, corrosion resistance, impact-abrasion resistance, and long-term economy.

A514 steel plate

ASTM A514 is most commonly used as structural steel in cranes and large heavy-load machines.

Overview:

Commonly used as structural steel in cranes or large heavy-load machines, A514 offers high strength with weldable, machinable properties.

Also referred to as T-1 steel.

Quenched and tempered for increased strength.

Available in eight grades: B, S, H, Q, E, F, A and P.

Available in heavy plate thicknesses (3-inches or greater).

Suitable in lower temperatures. Charpy impact test results for specific climates available.

Available Sizes

stocks the following standard sizes, but other sizes may be available for special orders.

| GRADE | THICKNESS | WIDTH | LENGTH |

| GRADE B | 3/16" – 1 1/4" | 48" – 120" | UP TO 480" |

| GRADE S | 3/16" – 2 1/2" | 48" – 120" | UP TO 480" |

| GRADE H | 3/16" – 2" | 48" – 120" | UP TO 480" |

| GRADE Q | 3/16" – 8" | 48" – 120" | UP TO 480" |

| GRADE E | 3/16" – 6" | 48" – 120" | UP TO 480" |

| GRADE F | 3/16" – 2 1/2" | 48" – 120" | UP TO 480" |

| GRADE A | INQUIRE | INQUIRE | INQUIRE |

| GRADE P | INQUIRE | INQUIRE | INQUIRE |

MATERIAL PROPERTIES

The following material properties are ASTM specifications and will be confirmed on the Mill Test Report.

| GRADE | YIELD POINT (KSI) | TENSILE STRENGTH (KSI) | MIN. 8” ELONGATION % |

| 3/4" OR LESS THICKNESS | 100 | 110-130 | 18 |

| GREATER THAN 3/4" TO 2.5" THICKNESS | 100 | 110-130 | 18 |

| GREATER THAN 2.5" TO 6" THICKNESS | 90 | 100-130 | 16 |

Technical data

CHEMICAL COMPOSITION

The following composition properties are ASTM specifications for A514 steel grades.

| Grade B | |

| CARBON | 0.12-0.21% |

| MANGANESE | 0.70-1.00% |

| PHOSPHORUS MAX | 0.030% |

| SULFUR MAX | 0.030% |

| SILICON | 0.20-0.35% |

| CHROMIUM | 0.40-0.65% |

| MOLYBDENUM | 0.15-0.25% |

| VANADIUM | 0.03-0.08% |

| TITANIUM | 0.01-0.10% |

| BORON | 0.0005-0.005% |

| Grade S | |

| CARBON | 0.11-0.21% |

| MANGANESE | 1.10-1.50% |

| PHOSPHORUS MAX | 0.030% |

| SULFUR MAX | 0.020% |

| SILICON | 0.15-0.45% |

| MOLYBDENUM | 0.10-0.60% |

| VANADIUM | 0.06% |

| BORON | 0.001-0.005% |

| COLUMBIUM MAX | 0.06% |

| Grade H | |

| CARBON | 0.12-0.21% |

| MANGANESE | 0.95-1.30% |

| PHOSPHORUS MAX | 0.030% |

| SULFUR MAX | 0.030% |

| SILICON | 0.20-0.35% |

| NICKEL | 0.30-0.70% |

| CHROMIUM | 0.40-0.65% |

| MOLYBDENUM | 0.20-0.30% |

| VANADIUM | 0.03-0.08% |

| BORON | 0.0005-0.005% |

| Grade Q | |

| CARBON | 0.14-0.21% |

| MANGANESE | 0.95-1.30% |

| PHOSPHORUS MAX | 0.030% |

| SULFUR MAX | 0.030% |

| SILICON | 0.15-0.35% |

| NICKEL | 1.20-1.50% |

| CHROMIUM | 1.00-1.50% |

| MOLYBDENUM | 0.40-0.60% |

| VANADIUM | 0.03-0.08% |

| Grade E | |

| CARBON | 0.12-0.20% |

| MANGANESE | 0.40-0.70% |

| PHOSPHORUS MAX | 0.030% |

| SULFUR MAX | 0.030% |

| SILICON | 0.20-0.40% |

| CHROMIUM | 1.40-20% |

| MOLYBDENUM | 0.40-0.60% |

| TITANIUM | 0.01-0.10% |

| BORON | 0.001-0.005% |

| CARBON | 0.10-0.20% |

| MANGANESE | 0.60-1.00% |

| PHOSPHORUS MAX | 0.030% |

| SULFUR MAX | 0.030% |

| SILICON | 0.15-0.35% |

| NICKEL | 0.70-1.00% |

| CHROMIUM | 0.40-0.65% |

| MOLYBDENUM | 0.40-0.60% |

| VANADIUM | 0.03-0.08% |

| COPPER | 0.15-0.50% |

| BORON | 0.0005-0.006% |

| Grade A | |

| CARBON | 0.15-0.21% |

| MANGANESE | 0.80-1.10% |

| PHOSPHORUS MAX | 0.030% |

| SULFUR MAX | 0.030% |

| SILICON | 0.40-0.80% |

| CHROMIUM | 0.50-0.80% |

| MOLYBDENUM | 0.18-0.28% |

| ZIRCONIUM | 0.05-0.15% |

| BORON | 0.0025% MAX |

| Grade P | |

| CARBON | 0.12-0.21% |

| MANGANESE | 0.95-1.30% |

| PHOSPHORUS MAX | 0.030% |

| SULFUR MAX | 0.030% |

| SILICON | 0.20-0.35% |

| NICKLE | 1.20-1.50% |

| CHROMIUM | 0.85-1.20% |

| MOLYBDENUM | 0.45-0.60% |

| BORON | 0.001-0.005% MAX |

Factory profile

Adhering to the tenet of "integrity first, quality for survival", the company has established a complete marketing channel of "based in North China, radiating the whole country, and facing the world", and has not only established a solid strategic partnership with many domestic and foreign enterprises.We have been committed to product development, production and sales, after more than ten years of efforts, our products have been widely used in various fields.

Packing method: Packing according to customer's requirement.

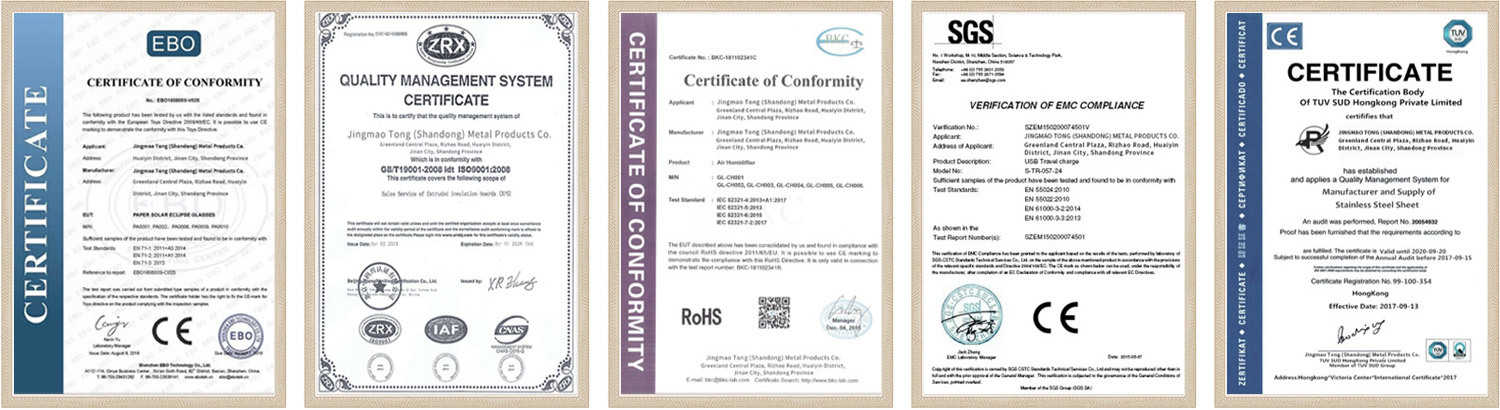

The company has more than 110,000 square meters of production and processing base, fully introduced the international advanced modern automatic production and processing equipment, and took the lead in passing the ISO9001, TS16949, BV, SGS and other international well-known institutions certification.The products are mainly exported to Italy, Mexico, South Korea, Israel, Turkey, India, Pakistan, Kyrgyzstan, Oman, Kazakhstan, Vietnam, Myanmar and other countries. The company's supply is sufficient, the variety is complete, order production is fast, welcome domestic and foreign manufacturers, traders to contact us.

Company Advantages

1. We are a large-scale production enterprise integrating production, research and development, and can customize the products required by customers.

2. We have a perfect after-sales service system, which can track the problems encountered by customers in production at any time and provide corresponding technical support, so as to share our high-quality resources with customers.

3. After more than ten years of development, the company has complete product varieties and large inventory, which can be delivered in the shortest time.

4. Free samples are available.

5. With obvious price advantage, the company has complete production process, from raw materials to finished products integrated production can maximize the cost savings.

QUESTIONS AND ANSWERS

1. Can you make a discount on your price?

2. Do you have any compensation if the goods do not arrive on time?

3. Can I add my own Logo to the purchased products?

4. Can you compensate for the damage in transit?

APPLICATION FIELD

Steel Structure

Steel Structure

Petroleum

Petroleum

Boiler

Boiler

Architecture

Architecture

A Ship

A Ship

Bridge

Bridge

Chemical Plant

Chemical Plant

Oceanographic Engineering

Oceanographic Engineering

RELATED PRODUCTS

GET A FREE QUOTE