Welcome to Jingmao Tong (Shandong) Metal Products Co., Ltd.

Email :business@sdhmsteel.com Whatsapp :+8613176025308

PRODUCT CENTER

Stainless Steel 410

Product Details

Product Introduction

Stainless steel 410 is the basic, general purpose martensitic stainless steel that is used for highly stressed parts and provides good corrosion resistance plus high strength and hardness. 410 stainless steel contains a minimum of 11.5% chromium which is just sufficient enough to demonstrate corrosion resistance properties in mild atmospheres, steam, and many mild chemical environments.

It is a general purpose grade that is often supplied in the hardened but still machineable condition for applications where high strength and moderate heat and corrosion resistance are required. Alloy 410 displays maximum corrosion resistance when it’s been hardened, tempered, and then polished.

Applications

Grade 410 stainless steels find applications in the following:

-

Bolts, screws, bushings and nuts

-

Petroleum fractionating structures

-

Shafts, pumps and valves

-

Mine ladder rungs

-

Gas turbines

Technical Data

Chemical Composition

| Grade | C | Mn | Si | P | S | Cr | Ni | |

|

410 |

min. |

- |

- |

- |

- |

- |

11.5 |

0.75 |

Mechanical Properties

| Tempering Temperature (°C) | Tensile Strength (MPa) | Yield Strength 0.2% Proof (MPa) | Elongation (% in 50 mm) | Hardness Brinell (HB) | Impact Charpy V (J) |

|

Annealed * |

480 min |

275 min |

16 min |

- |

- |

|

204 |

1475 |

1005 |

11 |

400 |

30 |

|

316 |

1470 |

961 |

18 |

400 |

36 |

|

427 |

1340 |

920 |

18.5 |

405 |

# |

|

538 |

985 |

730 |

16 |

321 |

# |

|

593 |

870 |

675 |

20 |

255 |

39 |

|

650 |

300 |

270 |

29.5 |

225 |

80 |

* Annealed properties of cold finished bar, which pertain to Condition A of ASTM A276.

# Tempering of grade 410 steels should be avoided at temperatures of 425-600 °C, owing to associated low impact resistance.

Physical Properties

| Grade | Density (kg/m3) | Elastic Modulus (GPa) | Mean Coefficient of Thermal Expansion (μm/m/°C) | Thermal Conductivity (W/m.K) | Specific Heat 0-100 °C (J/kg.K) |

Electrical Resistivity (nΩ.m)

|

|||

| 0-100 °C | 0-315 °C | 0-538 °C | at 100 °C | at 500 °C | |||||

|

410 |

7800 |

200 |

9.9 |

11 |

11.5 |

24.9 |

28.7 |

460 |

570 |

Grade Specification Comparison

| Grade | UNS No | Old British | Euronorm | Swedish SS | Japanese JIS | ||

| BS | En | No | Name | ||||

|

410 |

S41000 |

410S21 |

56A |

1.4006 |

X12Cr13 |

2302 |

SUS 410 |

Possible Alternative Grades

| Grade | Reasons for choosing the grade |

|

416 |

High machinability is required, and the lower corrosion resistance of 416 is acceptable. |

|

420 |

A higher hardened strength or hardness than can be obtained from 410 is needed. |

|

440C |

A higher hardened strength or hardness than can be obtained even from 420 is needed. |

Factory profile

Adhering to the tenet of "integrity first, quality for survival", the company has established a complete marketing channel of "based in North China, radiating the whole country, and facing the world", and has not only established a solid strategic partnership with many domestic and foreign enterprises.We have been committed to product development, production and sales, after more than ten years of efforts, our products have been widely used in various fields.

Packing method: Packing according to customer's requirement.

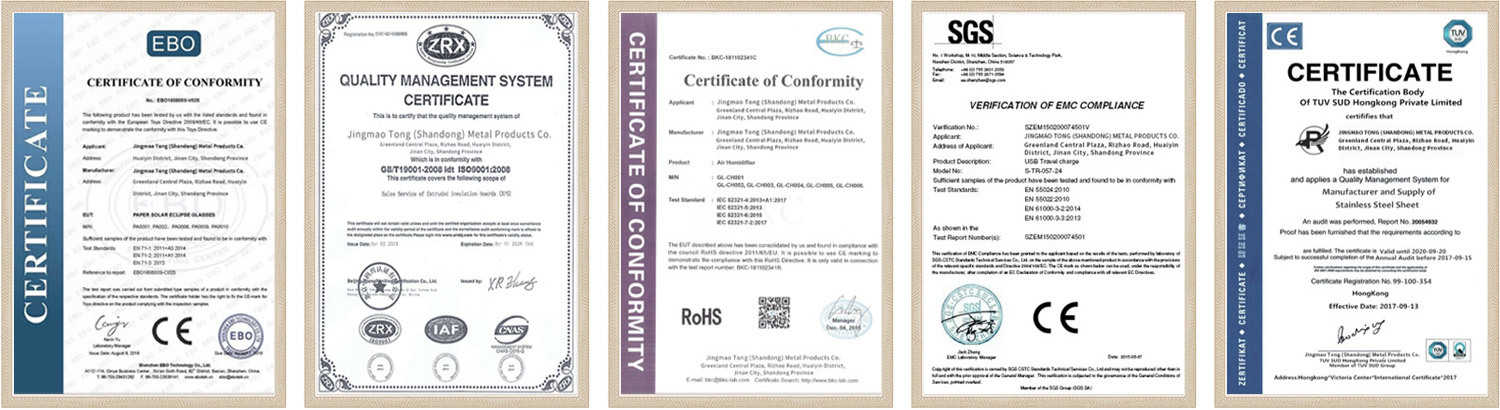

The company has more than 110,000 square meters of production and processing base, fully introduced the international advanced modern automatic production and processing equipment, and took the lead in passing the ISO9001, TS16949, BV, SGS and other international well-known institutions certification.The products are mainly exported to Italy, Mexico, South Korea, Israel, Turkey, India, Pakistan, Kyrgyzstan, Oman, Kazakhstan, Vietnam, Myanmar and other countries. The company's supply is sufficient, the variety is complete, order production is fast, welcome domestic and foreign manufacturers, traders to contact us.

Company Advantages

1. We are a large-scale production enterprise integrating production, research and development, and can customize the products required by customers.

2. We have a perfect after-sales service system, which can track the problems encountered by customers in production at any time and provide corresponding technical support, so as to share our high-quality resources with customers.

3. After more than ten years of development, the company has complete product varieties and large inventory, which can be delivered in the shortest time.

4. Free samples are available.

5. With obvious price advantage, the company has complete production process, from raw materials to finished products integrated production can maximize the cost savings.

We have a large stock and delivery time is 3 to 7 days after rec

QUESTIONS AND ANSWERS

1. Can you make a discount on your price?

2. Do you have any compensation if the goods do not arrive on time?

3. Can I add my own Logo to the purchased products?

4. Can you compensate for the damage in transit?

APPLICATION FIELD

Steel Structure

Steel Structure

Petroleum

Petroleum

Boiler

Boiler

Architecture

Architecture

A Ship

A Ship

Bridge

Bridge

Chemical Plant

Chemical Plant

Oceanographic Engineering

Oceanographic Engineering

RELATED PRODUCTS

GET A FREE QUOTE