Welcome to Jingmao Tong (Shandong) Metal Products Co., Ltd.

Email :business@sdhmsteel.com Whatsapp :+8613176025308

PRODUCT CENTER

ASTM A335 P91 Alloy Steel Pipe

it is applicable in the power industry and petrochemical plants.

Product Details

Product introduction

Astm A335 standard specication for seamless ferritic alloy-steel pipe for high-temperature service

ASTM A335 standard is issued under the fixed designation A 335/A 335M; the number immediately following the designation indicates the year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript epsilon ( ュ) indicates an editorial change since the last revision or reapproval.

Scope

1.1This specification covers nominal (average) wall seamless alloy-steel pipe intended for high-temperature service (Mote 1). Pipe ordered to this specification shall be suitable for bending, flanging (vanstoning), and similar forming operations, and for fusion welding. Selection will depend upon design, service conditions, mechanical properties, and high-temperature characteristics.

NOTE 1 Α Appendix X1 lists the sizes and wall thicknesses of pipe which may be obtained under current commercial practice.

1.2 Several grades of ferritic steels (Note 2) are covered.

Note 2

ΑFerritic steels in this specification are defined as low and intermediate-alloy steels containing up to and including 10% chromium.

1.3 Supplementary requirements (S1 to S7) of an optional nature are provided. These supplementary requirements call for additional tests to be made, and when desired, shall be so stated in the order together with the number of such tests required.

1.4 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with specification. The inch-pound units shall apply unless the "M" designation of this specification is specified in the order.

Note 3ΑThe dimensionless designator NPS (nominal pipe size) has been substituted in this standard for such traditional terms as "nominal diameter," "size," and "nominal size."

Material & Manufacture

Pipe may be either hot finished or cold drawn with the finishing heat treatment noted below.

Transverse or Longitudinal Tension Test and Flattening Test, Hardness Test, or Bend TestMechanical Tests Specified

For material heat treated in a batch-type furnace, tests shall be made on 5% of the pipe from each treated lot. For small lots, at least one pipe shall be tested.

For material heat treated by the continuous process, tests shall be made on a sufficient number of pipe to constitute 5% of the lot, but in no case less than 2 pipe.

Notes for Hardness Test:

P91 shall not have a hardness not exceeding 250 HB/265 HV [25HRC].

Notes for Bend Test:

For pipe whose diameter exceeds NPS 25 and whose diameter to wall thickness ratio is 7.0 or less shall be subjected to the bend test instead of the flattening test.

Other pipe whose diameter equals or exceeds NPS 10 may be given the bend test in place of the flattening test subject to the approval of the purchaser.

The bend test specimens shall be bent at room temperature through 180 without cracking on the outside of the bent portion.

Hydrostatic Test

The inside diameter of the bend shall be 1 inch [25 mm].

Each length of pipe shall be Hydro tested, at option of manufacture nondestructive electric testing can be used.

Technical data

Chemical Composition:

| Grade | C | Mn | P | S | Si | Mo |

| P1 | 0.10-0.20 | 0.30-0.80 | 0.025 | 0.025 | 0.10-0.50 | 0.44-0.65 |

| P2 | 0.10-0.20 | 0.30-0.61 | 0.025 | 0.025 | 0.10-0.30 | 0.44-0.65 |

| P5 | 0.15max | 0.30-0.60 | 0.025 | 0.025 | 0.50max | 0.45-0.65 |

| P5b | 0.15max | 0.30-0.60 | 0.025 | 0.025 | 1.00-2.00 | 0.45-0.65 |

| P5c | 0.12max | 0.30-0.60 | 0.025 | 0.025 | 0.50max | 0.45-0.65 |

| P9 | 0.15max | 0.30-0.60 | 0.025 | 0.025 | 0.25-1.00 | 0.90-1.10 |

| P11 | 0.05-0.15 | 0.30-0.60 | 0.025 | 0.025 | 0.50-1.00 | 0.44-0.65 |

| P12 | 0.05-0.15 | 0.30-0.61 | 0.025 | 0.025 | 0.50max | 0.44-0.65 |

| P15 | 0.05-0.15 | 0.30-0.60 | 0.025 | 0.025 | 1.15-1.65 | 0.44-0.65 |

| P21 | 0.05-0.15 | 0.30-0.60 | 0.025 | 0.025 | 0.50max | 0.80-1.06 |

| P22 | 0.05-0.15 | 0.30-0.60 | 0.025 | 0.025 | 0.50max | 0.87-1.13 |

| P23 | 0.04-0.10 | 0.10-0.60 | 0.030max | 0.010max | 0.50max | 0.05-1.30 |

Mechanical Properties

| Mechanical properties | P1,P2 | P12 | P23 | P91 | P92,P11 | P122 |

| Tensile strength | 380 | 415 | 510 | 585 | 620 | 620 |

| Yield strength | 205 | 220 | 400 | 415 | 440 | 400 |

Heat Treatment Requirements

| Grade | Heat Treatment Type P5, P9, P11, and P22 |

Normalizing Temperature Range F [C] | Subcritical Annealing or Tempering Temperature Range F [C] |

| A335 P5 (b,c) | Full or Isothermal Anneal | ||

| Normalize and Temper | ***** | 1250 [675] | |

| Subcritical Anneal (P5c only) | ***** | 1325 – 1375 [715 - 745] | |

| A335 P9 | Full or Isothermal Anneal | ||

| Normalize and Temper | ***** | 1250 [675] | |

| A335 P11 | Full or Isothermal Anneal | ||

| Normalize and Temper | ***** | 1200 [650] | |

| A335 P22 | Full or Isothermal Anneal | ||

| Normalize and Temper | ***** | 1250 [675] | |

| A335 P91 | Normalize and Temper | 1900-1975 [1040 - 1080] | 1350-1470 [730 - 800] |

| Quench and Temper | 1900-1975 [1040 - 1080] | 1350-1470 [730 - 800] |

| Heat Treatment | A / N+T | N+T / Q+T | N+T |

Factory profile

Adhering to the tenet of "integrity first, quality for survival", the company has established a complete marketing channel of "based in North China, radiating the whole country, and facing the world", and has not only established a solid strategic partnership with many domestic and foreign enterprises.We have been committed to product development, production and sales, after more than ten years of efforts, our products have been widely used in various fields.

Packing method: Packing according to customer's requirement.

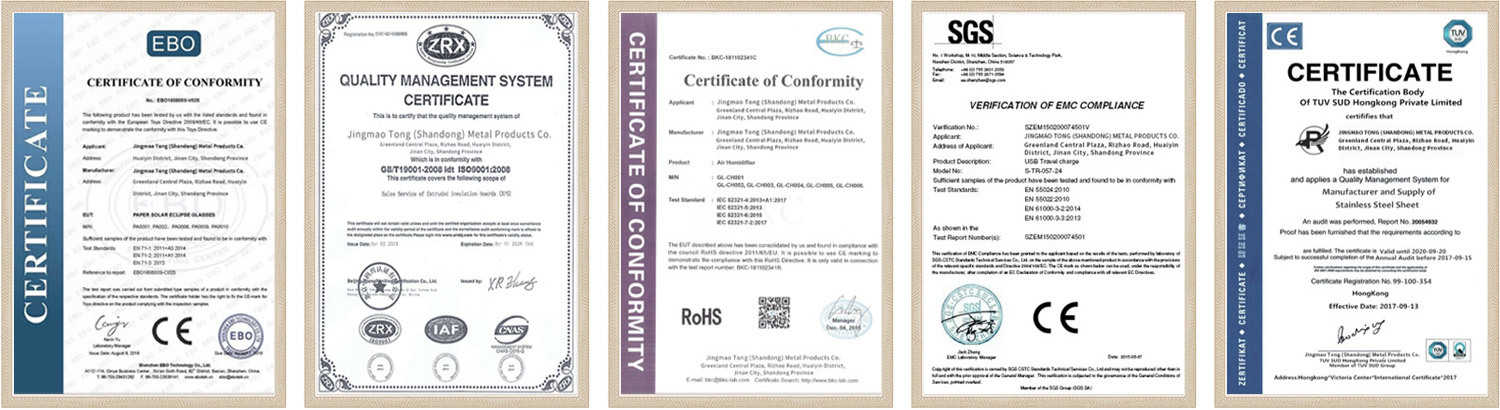

The company has more than 110,000 square meters of production and processing base, fully introduced the international advanced modern automatic production and processing equipment, and took the lead in passing the ISO9001, TS16949, BV, SGS and other international well-known institutions certification.The products are mainly exported to Italy, Mexico, South Korea, Israel, Turkey, India, Pakistan, Kyrgyzstan, Oman, Kazakhstan, Vietnam, Myanmar and other countries. The company's supply is sufficient, the variety is complete, order production is fast, welcome domestic and foreign manufacturers, traders to contact us.

Company Advantages

1. We are a large-scale production enterprise integrating production, research and development, and can customize the products required by customers.

2. We have a perfect after-sales service system, which can track the problems encountered by customers in production at any time and provide corresponding technical support, so as to share our high-quality resources with customers.

3. After more than ten years of development, the company has complete product varieties and large inventory, which can be delivered in the shortest time.

4. Free samples are available.

5. With obvious price advantage, the company has complete production process, from raw materials to finished products integrated production can maximize the cost savings.

QUESTIONS AND ANSWERS

1. Can you make a discount on your price?

2. Do you have any compensation if the goods do not arrive on time?

3. Can I add my own Logo to the purchased products?

4. Can you compensate for the damage in transit?

APPLICATION FIELD

Steel Structure

Steel Structure

Petroleum

Petroleum

Boiler

Boiler

Architecture

Architecture

A Ship

A Ship

Bridge

Bridge

Chemical Plant

Chemical Plant

Oceanographic Engineering

Oceanographic Engineering

RELATED PRODUCTS

GET A FREE QUOTE