Welcome to Jingmao Tong (Shandong) Metal Products Co., Ltd.

Email :business@sdhmsteel.com Whatsapp :+8613176025308

How to deal with aluminum after welding

Release time:

2022-08-12

Residual flux and welding slag left in and near the weld after welding will destroy the passivation film on the surface of aluminum, and sometimes corrosion aluminum parts, which should be cleaned up. The workpiece with simple shape and general requirements can be cleaned by simple methods such as hot water washing or steam blowing brush.

Residual flux and welding slag left in and near the weld after welding will destroy the passivation film on the surface of aluminum, and sometimes corrosion aluminum parts, which should be cleaned up. The workpiece with simple shape and general requirements can be cleaned by simple methods such as hot water washing or steam blowing brush. The aluminum parts with high requirements and complex shape can be washed with a hard brush in hot water, and then soaked in 2%-3% chromic anhydride aqueous solution or potassium dichromate solution in about 60℃ ~ 80℃ for 5 min ~ 10 min, and washed with a hard brush, and then washed in hot water, dried in an oven, or dried with hot air, and also dried naturally.

(2) Post-welding heat treatment Aluminum containers generally do not require heat treatment after welding.

Recycling Optional recycling

Aluminum is one of the most important non-ferrous metals. Because of its good properties (low density, good plasticity and formability) and easy recycling, pure aluminum and aluminum alloys have become important basic materials in home appliances. It is widely used in the remaking of hot parts and conductive parts of household appliances. The recycling of waste aluminum has become the most important part of non-ferrous metal recycling, and its energy consumption and recycling cost are much lower than that of primary aluminum production (about 10%).

Latest News

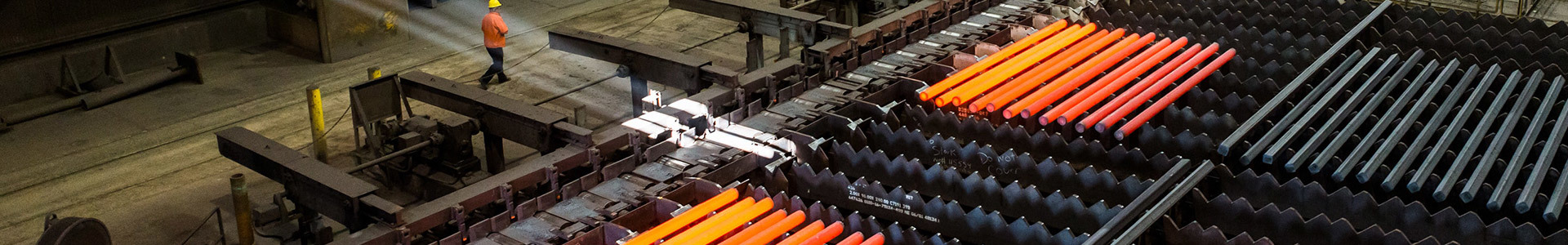

Production method and classification of steel pipe

According to the production method, seamless steel pipe can be divided into: hot rolled seamless pipe, cold drawn pipe, precision steel pipe, hot expansion pipe, cold spin pipe and extrusion pipe, etc. Seamless steel pipe is made of high quality carbon steel or alloy steel, hot rolled, cold rolled (drawing)

2022-08-23

Pipes for pipes. Such as: water, gas pipe, steam pipe with seamless pipe, oil transmission pipe, oil and natural gas trunk pipe. Agricultural irrigation water faucet belt pipe and spray irrigation pipe.

2022-08-23

Production method of steel pipe

Steel pipes are divided into seamless steel pipes and welded steel pipes. The production process of seamless steel pipe is to Pierce the solid tube blank or steel ingot into hollow tube, and then roll it into the desired size of steel pipe.

2022-08-23

Steel coil, also known as coil steel. The steel is rolled by hot pressing and cold pressing. In order to facilitate storage and transportation, convenient for various processing (such as processing into steel plate, steel belt, etc.).

2022-08-23

The use of aluminum composition

Casting products: castings. The substrate as the anode, placed in the electrolyte for electrolysis, artificially formed a layer of protective oxide film on the surface of the substrate to form aluminum oxide.

2022-08-23

Specifications for the use of aluminum in buildings

Deformed aluminum alloy is divided into rust-proof aluminum alloy, duralumin, super duralumin and special aluminum according to its properties and uses. Generally, industrial pure aluminum (L1 ~ L1), rust-proof aluminum alloy (LF2, LF21, etc.) and forged aluminum (LD2) are used in construction.

2022-08-23