Welcome to Jingmao Tong (Shandong) Metal Products Co., Ltd.

Email :business@sdhmsteel.com Whatsapp :+8613176025308

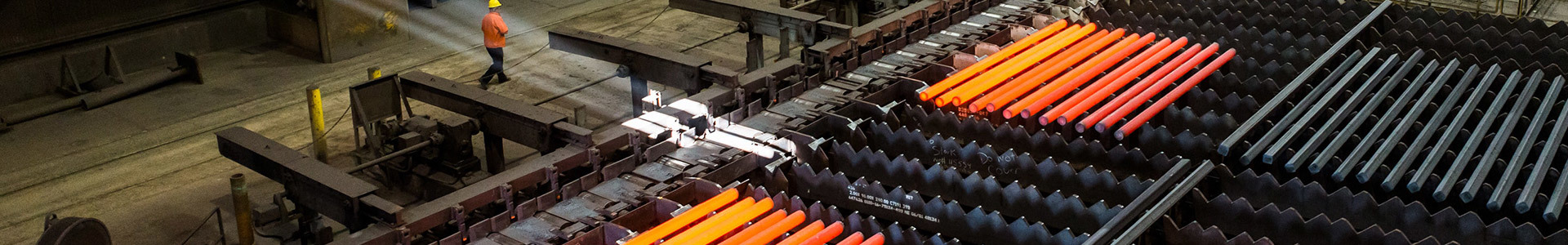

Production method of steel pipe

Release time:

2022-08-23

Steel pipes are divided into seamless steel pipes and welded steel pipes. The production process of seamless steel pipe is to Pierce the solid tube blank or steel ingot into hollow tube, and then roll it into the desired size of steel pipe.

Steel pipes are divided into seamless steel pipes and welded steel pipes. The production process of seamless steel pipe is to Pierce the solid tube blank or steel ingot into hollow tube, and then roll it into the desired size of steel pipe. The different methods of perforation and rolling constitute the different methods of producing seamless steel pipe. The production process of welded steel pipe is to bend the tube blank (steel plate or strip) into a tubular shape, and then weld the gap into a steel pipe. Because of the different forming and welding methods used in mining, the different methods of producing welded steel pipe are constituted.

Seamless steel pipe is mainly produced by hot rolling method. Extrusion method is mainly used in the production of low plastic high alloy steel pipe or deformed steel pipe and composite gold pipe. By cold rolling and cold drawing, the hot rolled pipe can be continuously processed into small diameter and thin wall steel pipe. Welding steel pipe process is simple, high production efficiency, low cost, product varieties are expanding. Seamless steel pipe and welded steel pipe

Seamless steel pipe is made of high quality carbon steel or alloy steel, hot rolled, cold rolled (drawing).

2. Welded steel pipe is divided into furnace welded pipe, electric welding (resistance welding) pipe and automatic arc welding pipe due to its different welding forms, which are divided into straight seam welded pipe and spiral welded pipe. Because of the shape of its end, it is also divided into circular welded pipe and special-shaped (square, flat, etc.) welded pipe.

Welded steel pipe is made of rolled tubular steel plate welded by joint or spiral joint. In the manufacturing method, it is divided into welding steel pipe for low pressure fluid transmission, spiral welded steel pipe, direct coiled welded steel pipe, electric welded pipe, etc. Seamless steel pipe can be used in various industries of liquid pressure pipe and gas pipe, etc. Welding pipe can be used for water pipe, gas pipe, heating pipe, electrical pipe and so on.

Latest News

Production method and classification of steel pipe

According to the production method, seamless steel pipe can be divided into: hot rolled seamless pipe, cold drawn pipe, precision steel pipe, hot expansion pipe, cold spin pipe and extrusion pipe, etc. Seamless steel pipe is made of high quality carbon steel or alloy steel, hot rolled, cold rolled (drawing)

2022-08-23

Pipes for pipes. Such as: water, gas pipe, steam pipe with seamless pipe, oil transmission pipe, oil and natural gas trunk pipe. Agricultural irrigation water faucet belt pipe and spray irrigation pipe.

2022-08-23

Production method of steel pipe

Steel pipes are divided into seamless steel pipes and welded steel pipes. The production process of seamless steel pipe is to Pierce the solid tube blank or steel ingot into hollow tube, and then roll it into the desired size of steel pipe.

2022-08-23

Steel coil, also known as coil steel. The steel is rolled by hot pressing and cold pressing. In order to facilitate storage and transportation, convenient for various processing (such as processing into steel plate, steel belt, etc.).

2022-08-23

The use of aluminum composition

Casting products: castings. The substrate as the anode, placed in the electrolyte for electrolysis, artificially formed a layer of protective oxide film on the surface of the substrate to form aluminum oxide.

2022-08-23

Specifications for the use of aluminum in buildings

Deformed aluminum alloy is divided into rust-proof aluminum alloy, duralumin, super duralumin and special aluminum according to its properties and uses. Generally, industrial pure aluminum (L1 ~ L1), rust-proof aluminum alloy (LF2, LF21, etc.) and forged aluminum (LD2) are used in construction.

2022-08-23