Welcome to Jingmao Tong (Shandong) Metal Products Co., Ltd.

Email :business@sdhmsteel.com Whatsapp :+8613176025308

Welding methods for aluminum

Release time:

2022-08-12

Almost all kinds of welding methods can be used for welding aluminum and aluminum alloy, but the adaptability of aluminum and aluminum alloy to various welding methods is different, and each welding method has its own application.

Almost all kinds of welding methods can be used for welding aluminum and aluminum alloy, but the adaptability of aluminum and aluminum alloy to various welding methods is different, and each welding method has its own application. Gas welding and electrode arc welding method, simple equipment, easy to operate. Gas welding can be used to repair welding of aluminum sheet and castings with low welding quality requirements. Electrode arc welding can be used to repair welding of aluminum alloy castings. Inert gas shielded welding (TIG or MIG) is the most widely used welding method for aluminum and aluminum alloys. Aluminum and aluminum alloy sheet can be tungsten AC argon arc welding or tungsten pulse argon arc welding. Aluminum and aluminum alloy thick plates can be tungsten helium arc welding, argon-helium mixed tungsten gas welding, fusion gas welding, pulse fusion gas welding. More and more applications of pulsed MIG welding (argon or argon/helium)

Latest News

Production method and classification of steel pipe

According to the production method, seamless steel pipe can be divided into: hot rolled seamless pipe, cold drawn pipe, precision steel pipe, hot expansion pipe, cold spin pipe and extrusion pipe, etc. Seamless steel pipe is made of high quality carbon steel or alloy steel, hot rolled, cold rolled (drawing)

2022-08-23

Pipes for pipes. Such as: water, gas pipe, steam pipe with seamless pipe, oil transmission pipe, oil and natural gas trunk pipe. Agricultural irrigation water faucet belt pipe and spray irrigation pipe.

2022-08-23

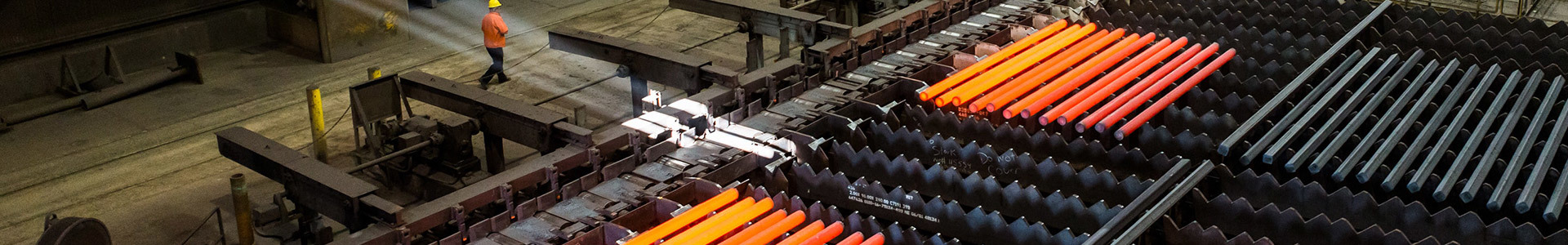

Production method of steel pipe

Steel pipes are divided into seamless steel pipes and welded steel pipes. The production process of seamless steel pipe is to Pierce the solid tube blank or steel ingot into hollow tube, and then roll it into the desired size of steel pipe.

2022-08-23

Steel coil, also known as coil steel. The steel is rolled by hot pressing and cold pressing. In order to facilitate storage and transportation, convenient for various processing (such as processing into steel plate, steel belt, etc.).

2022-08-23

The use of aluminum composition

Casting products: castings. The substrate as the anode, placed in the electrolyte for electrolysis, artificially formed a layer of protective oxide film on the surface of the substrate to form aluminum oxide.

2022-08-23

Specifications for the use of aluminum in buildings

Deformed aluminum alloy is divided into rust-proof aluminum alloy, duralumin, super duralumin and special aluminum according to its properties and uses. Generally, industrial pure aluminum (L1 ~ L1), rust-proof aluminum alloy (LF2, LF21, etc.) and forged aluminum (LD2) are used in construction.

2022-08-23

CONTACT US

Tel : +8613176025308

Email :business@sdhmsteel.com

Whatsapp :+8613176025308

Address :Jingmao Tong (Shandong) Metal Products Co., Ltd.

GET A FREE QUOTE

Copyright : Jingmao Tong (Shandong) Metal Products Co., Ltd. Powerby : 300.cn jinan2 Seo Tags business license